The Critical Role of a spring manufacturer in Modern Industry

In the vast world of manufacturing, not all components grab attention, but some are absolutely vital for product performance. Among these, springs are the unsung heroes that provide force, motion, and flexibility in countless products. Whether it’s the suspension system in a car, the recoil mechanism in a power tool, or the tactile click in a keyboard, you’ll find a spring at work behind the scenes. That’s why choosing the right spring manufacturer is a decision that can have long-term implications for your product quality, reliability, and customer satisfaction.

Springs may look simple, but their design, materials, and production precision demand specialized knowledge and state-of-the-art equipment. In this article, we’ll explore the importance of springs in manufacturing, what makes a reliable spring manufacturer, and how these experts are shaping the next generation of mechanical innovation.

What Does a Spring Manufacturer Actually Do?

A spring manufacturer is a company that designs and produces springs for various applications across industrial sectors. This includes common spring types such as:

- Compression springs: Used to resist compressive forces

- Extension springs: Used to absorb and store energy in a pulling force

- Torsion springs: Function through rotational or twisting force

- Wire forms and flat springs: Custom bent wire or sheet metal for specialized applications

These components vary in size, strength, and complexity—ranging from tiny springs used in watches and electronics to heavy-duty industrial springs used in aerospace and automotive industries.

A top-tier spring manufacturer doesn’t just churn out identical parts; it works with engineers, designers, and procurement teams to create springs tailored to specific loads, tolerances, environments, and operating conditions.

See also: AI Face Swap Technology in Live Performance Augmentation

Why Choosing the Right spring manufacturer Matters

1. Precision Engineering

Springs are engineered to perform under very specific conditions. A small deviation in force, diameter, or tension can cause a product to fail. Therefore, a reliable spring manufacturer ensures dimensional accuracy, repeatability, and material consistency through:

- CNC coiling machines

- Laser measuring systems

- Optical comparators

- Spring testers for load and fatigue analysis

Whether you need one prototype or a million identical springs, consistency is critical.

2. Material Expertise

The right spring material depends on your product’s environmental exposure, expected cycle life, and required load. A professional spring manufacturer will guide you through materials like:

- Stainless steel (for corrosion resistance)

- High-carbon steel (for high-strength applications)

- Phosphor bronze or beryllium copper (for conductivity and non-magnetic needs)

- Inconel or other superalloys (for high-temperature or high-stress environments)

This ensures that the springs used will not corrode, deform, or break prematurely.

3. Customization and Prototyping

Off-the-shelf springs may work for basic applications, but many industries require custom solutions. A good spring manufacturer will offer:

- Custom design and coiling

- CAD-assisted modeling

- Rapid prototyping

- Short-run manufacturing

These services are particularly useful for R&D, product development, and specialized machinery where standard springs won’t suffice.

Industries That Rely Heavily on Spring Manufacturers

✔ Automotive and Transportation

Springs are essential in suspensions, clutches, brake systems, and even door locks. A spring must withstand repeated stress over years of use while performing with accuracy.

✔ Medical Devices

In this field, precision and sterilizability are vital. From inhalers to surgical tools and dental equipment, custom micro-springs are used in high-stakes environments where failure is not an option.

✔ Consumer Electronics

From battery contacts to tactile feedback mechanisms in buttons, springs are everywhere in consumer devices. A specialized spring manufacturer can help achieve both function and miniaturization.

✔ Industrial Machinery

Large torsion and extension springs help drive mechanical operations, shock absorption, and tension control. These applications require durable materials and exact specifications.

✔ Aerospace and Defense

Springs used in this field must endure extreme forces, temperatures, and stress cycles. Every spring must pass rigorous inspections and meet military-grade or aerospace standards.

Traits of a Reliable Spring Manufacturer

✅ Technical Knowledge

A qualified spring manufacturer employs skilled engineers who understand spring dynamics, fatigue analysis, and production efficiency. They don’t just make springs—they solve design problems.

✅ Quality Certifications

Look for ISO 9001, IATF 16949 (for automotive), ISO 13485 (for medical), and RoHS compliance. These indicate consistent quality management systems and international recognition.

✅ Advanced Equipment

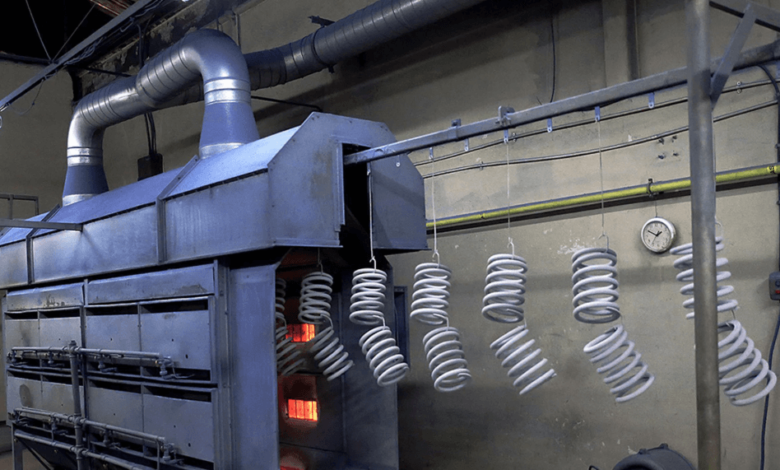

Modern manufacturers use high-speed coiling machines, grinding machines, stress-relief ovens, and 3D inspection tools to ensure tight tolerances and uniformity across batches.

✅ Strong Supply Chain and Export Capabilities

For international buyers, it’s important that the spring manufacturer understands customs procedures, export documentation, and packing standards. A supplier experienced in global shipping adds peace of mind.

✅ Client Support and Responsiveness

A good manufacturer answers questions quickly, collaborates effectively, and offers technical support from prototyping through full-scale production.

Emerging Trends in Spring Manufacturing

🌐 Smart Manufacturing

The use of sensors and IoT in machines is revolutionizing how springs are produced. Real-time data collection enables predictive maintenance, better quality control, and higher efficiency.

🌱 Sustainable Materials and Processes

Some manufacturers now use eco-friendly plating processes, recyclable packaging, and energy-saving machines. These practices align with ESG (Environmental, Social, Governance) goals of global clients.

🧠 Design-as-a-Service

Rather than simply responding to specifications, modern spring suppliers offer consultative design services—helping companies choose the right spring type, force, and material from the beginning.

Common Challenges When Sourcing Springs—and How a Good Manufacturer Solves Them

| Challenge | How a Good Manufacturer Helps |

| Miscommunication | Offers multilingual staff and clear documentation |

| Inconsistent quality | Implements multi-stage quality control processes |

| Limited customization | Offers full design and prototyping capabilities |

| Long lead times | Uses lean manufacturing and rapid response teams |

| Import/export complications | Has in-house logistics experts and shipping partners |

With the right spring manufacturer, these common pain points are eliminated or drastically reduced.

Real-World Example: Spring Innovation in Action

A German fitness-tech startup recently faced challenges sourcing precision compression springs for their smart wearable. After struggling with inconsistent local suppliers, they partnered with a spring manufacturer based in Asia.

The result?

- 50% reduction in cost

- 30% shorter lead time

- Improved durability and force consistency

- Faster go-to-market timeline

This case is just one of many that shows how a strategic manufacturing partner can transform operations and profitability.

Final Thoughts

Springs may be small, but their performance is huge. From the largest mechanical structures to the tiniest consumer devices, their role is indispensable. And behind every reliable spring is a dedicated spring manufacturer combining engineering expertise, modern technology, and global reach.

If your product depends on consistent motion, tension, or mechanical resilience, your choice of spring supplier matters more than ever. A capable and responsive spring manufacturer doesn’t just provide a part—they deliver precision, durability, and trust.

So, whether you’re launching a new product line or optimizing a legacy design, consider the value of partnering with a spring expert who understands your vision and delivers on it—one coil at a time.