Choose a Pigging System That Fits: A Strategic Guide for Pipeline-Based Industries

For industries that rely on liquid or viscous product transfer—such as food and beverage, personal care, household chemicals, pharmaceuticals, or paints—pipeline pigging systems have become essential tools for reducing waste and increasing productivity. However, the process to choose a pigging system that matches your specific production line isn’t as simple as selecting off-the-shelf equipment. The right system needs to be tailored to your process, product, infrastructure, and operational goals.

Choosing wisely can result in substantial returns in product recovery, reduced cleaning costs, and enhanced production flow. But a mismatch can mean added maintenance, inefficiencies, or even safety concerns. This guide walks you through how to strategically choose a pigging system suited to your facility’s specific needs and future growth plans.

Why Pigging Matters

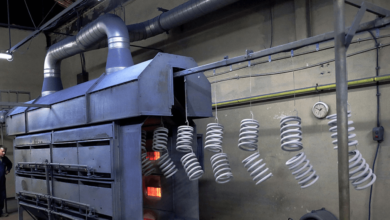

Before diving into how to choose a pigging system, it’s important to understand its significance. Pigging systems work by sending a projectile-like tool (the “pig”) through a pipeline to push product to its destination, clean residue from internal surfaces, or separate different product batches. These systems offer numerous benefits:

- Recovering valuable residual product

- Reducing water and chemical waste

- Preventing cross-contamination

- Reducing cleaning time and labor

- Improving environmental compliance

All of these advantages add up to operational cost savings and improved sustainability—key metrics for today’s performance-driven industries.

See also: AI Face Swap Technology in Live Performance Augmentation

Start with Your Product: One Size Doesn’t Fit All

One of the most critical considerations when you choose a pigging system is the nature of your product.

Ask yourself:

- Is the product viscous, oily, foamy, abrasive, or sensitive?

- Does the product leave behind stubborn residue?

- Is your product sensitive to cross-contamination?

- Are you processing multiple product types on the same line?

Thicker products like tomato paste or hand cream may require high-performance pigs that maintain a tight seal under pressure, while lightweight, low-viscosity products may need more gentle handling.

Moreover, the materials of both the pig and the pipeline need to be chemically compatible with your product to prevent degradation or contamination.

Understand Your Pipeline Infrastructure

No pigging system can operate effectively without integrating properly into your pipeline layout. Before choosing a pigging system, assess your infrastructure:

- Pipe diameter: This determines the pig size.

- Pipeline length: Affects the pig’s required travel distance and pressure.

- Bends and elbows: Not all pigs navigate tight corners equally well.

- Vertical vs. horizontal sections: This impacts pig movement, especially in manual or non-pressurized systems.

- Existing connections: You’ll need to install launchers, receivers, and potentially sensors or valves.

If your facility has multiple production lines, you may require multi-line pigging solutions or systems that can switch automatically between lines.

Manual vs. Automated: Choose Based on Scale and Budget

When you choose a pigging system, the level of automation should align with your scale of operations and process control needs.

- Manual systems: Best for small-scale operations with fewer batch changes. More labor-intensive but lower in upfront cost.

- Semi-automated systems: Operators control some functions, while the system handles others—ideal for mid-sized companies.

- Fully automated systems: Integrated with PLCs or SCADA systems, these provide full control and real-time feedback. Recommended for large-scale or continuous operations.

Automated systems may involve higher initial investment but offer faster payback through improved efficiency and fewer errors.

Choose the Right Pig: More Than Just a Cleaning Tool

The pig itself plays a vital role in overall system performance. When you choose a pigging system, ensure you select the correct pig type for your product and pipeline environment:

- Solid Pigs: Durable and effective for consistent pipelines with few curves.

- Foam Pigs: Lightweight and flexible—good for navigating tight bends.

- Sanitary Pigs: Used in food-grade or pharmaceutical applications; made from FDA-compliant materials.

- Smart Pigs: Equipped with sensors for pipeline inspection or data logging—more common in oil and gas but gaining interest elsewhere.

Additionally, consider whether the pig is reusable or disposable, and how it will be cleaned or stored between uses.

Safety and Regulatory Compliance

For industries where hygiene, health, and environmental concerns are high, choosing a compliant pigging system is non-negotiable.

- Sanitary Design: For food, beverage, or pharmaceutical applications, equipment must meet standards like FDA, EHEDG, or GMP.

- Pressure Ratings: The system must safely handle your normal and peak pipeline pressure.

- Operator Safety: Automated or semi-automated pigging systems reduce manual intervention, lowering the risk of human error or injury.

Also, when selecting system materials and design, always ensure they align with regulatory and environmental standards relevant to your industry.

Consider Maintenance and Spare Parts

When you choose a pigging system, think beyond the initial installation. Will your team be able to maintain it easily? Will you have access to spare parts quickly? Are training and technical support included?

Good systems are designed for durability, but no technology is immune to wear. Choose systems with:

- Easy-to-access components

- Replaceable seals and gaskets

- Software support (for automated systems)

- Local technical assistance or remote diagnostics

Systems with lower lifetime maintenance needs deliver better long-term value and uptime.

Choose a Provider with Expertise and Customization Capabilities

Finally, your pigging system is only as good as the company that supplies it. Look for vendors that:

- Offer customization based on your process

- Have experience in your specific industry

- Provide installation and commissioning support

- Offer documentation, compliance certificates, and training

- Maintain a responsive customer service and technical support team

Avoid vendors pushing generic systems that may not suit your needs. Instead, partner with providers who take the time to understand your operations and offer scalable, future-ready solutions.

Conclusion: Choose a Pigging System That Works for You

From small-scale startups to large manufacturing facilities, the decision to choose a pigging system should be based on a combination of technical, operational, and financial factors. There’s no one-size-fits-all answer—each system must align with your product type, production goals, hygiene standards, and budget.

With the right planning and the right partner, pigging systems can offer a transformative impact on your production line—reducing waste, increasing yield, and enhancing compliance. In a business world defined by margins and sustainability, that kind of upgrade isn’t just useful—it’s vital.